Sahastradhara Road, Near IT Park, Dehradun (UK) - 248001

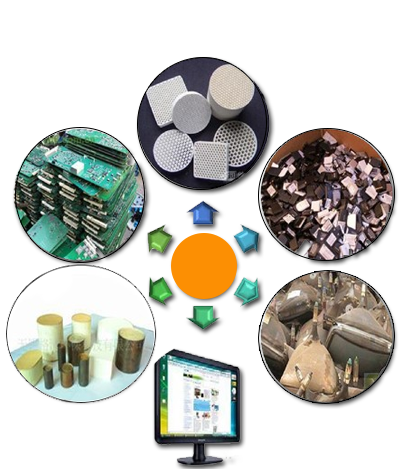

Urban Mining

E-waste mining is a radical solution for dealing with the glut of old computers, cell phones, DVDs and other electronic waste.

Rather than allowing electronic junk to simply amass in landfills, huge volumes of e-waste could be deposited into abandoned open pit mines. Using the same techniques used to process copper ore, valuable materials such as copper, iron, glass, gold and plastic could be extracted from electronic scrap.

The products in the electronics industry are made in an incredibly efficient way, and the same type of philosophy has to be used in dealing with the end-of-life issue. There are more than 550,000 abandoned hardrock mines in the USA. A single open pit mine has the capacity to hold 72 billion computers. Instead of viewing obsolete computer monitors and televisions as defunct sources of cathode ray tubes, we can look at it as a commodity. Mining is the best, most efficient way to process materials with low value content (like e-waste) and its an essentially no cost option.

Every year, mining produces approximately 300 times more waste than electronics do. E-waste is often richer in rare metals than virgin materials, containing 10 to 50 times higher copper content than copper ore. A cell phone contains five to ten times higher gold content than gold ore.

This solution could be an alternative to small-scale regional recycling programs that are employed today, that are often hazardous for the workers and inhabitants of that area. By using mining techniques, there is no need to ship e-waste overseas. E-waste mining can take place anywhere. The process could be done on a large concrete pad, rather than an old pit mine.

E-waste mining is both economically and environmentally sustainable. The method should be used only in mines that are void of groundwater problems. In its totality, the idea could mark a dramatic shift from the traditional method of disassembling electronics.

© Dev Bhoomi Recycling Pvt. Ltd. 2020 | Powered by ITArchs.com